| Name: | Truck-O-Liner commercial vehicle straightening and repair system |

|---|---|

| Brand: | Truck-O-Liner |

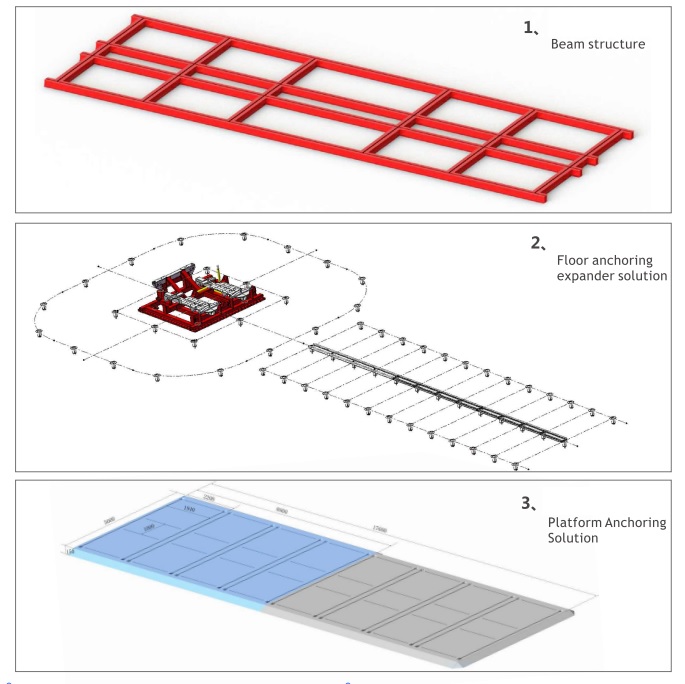

| Part 1: | floor beams and anchoring sytem |

| 2 options: | I-beam or floor anchoring |

| Part 2: | cab straightening system consists of cab bench, adapter kits, cab tower, pulling fixture and straightening hydraulic device |

| Part 3: | truck frame straightening system consists of frame press, hydraulic kits, straightening accessories, C-clamps |

| Current customers: | Benz trucks, Volvo trucks, Scania trucks, Foton Daimler Auman trucks |

| INQUIRY |

Product Description

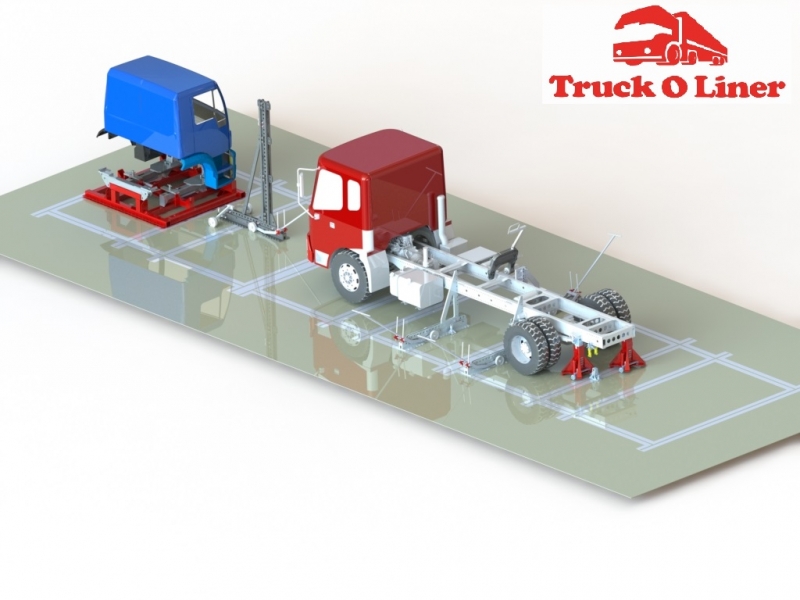

Commercial vehicle body collision repair equipment

Truck-O-Liner commercial vehicle straightening and repair system is the most professional and best-selling heavy commercial vehicle straightening and repair equipment in the world. This equipment has been used in workshops of Daimler Benz trucks, Volvo trucks, Scania trucks, Foton Daimler Auman trucks etc. This equipment can accurately straighten the damaged cab and repair the collision frame. Even a trailer with a total weight of 60 tons can be perfect straightened and corrected.

The equipment is made of high-strength alloy steel, which has high strength and long service life; it adopts the American high-pressure hydraulic system, which has strong tensile strength and is easy to straighten and repair. The equipment is uniquely designed, scientific and reasonable, and fully considers the deformation repair of the three dimensions of vehicle X.Y.Z. According to different truck models, it can be matched with special fixtures. The equipment is easy to operate, low in labor intensity, convenient and fast, and is the best choice for commercial vehicle maintenance workshops.

Truck-o-Liner heavy duty vehicle straightening equipment is suitable for trucks and engineering vehicles represented by heavy trucks, and also suitable for passenger vehicles represented by buses.

Part 1 Floor Anchoring System

The rail steel beam, the anchor seat fixing and the platform fixing are used to fix the vehicle, cab bench equipment, and frame straightening equipment. The purpose is to fix the vehicle, equipment, and floor system during work integrated into one body for power transmission.

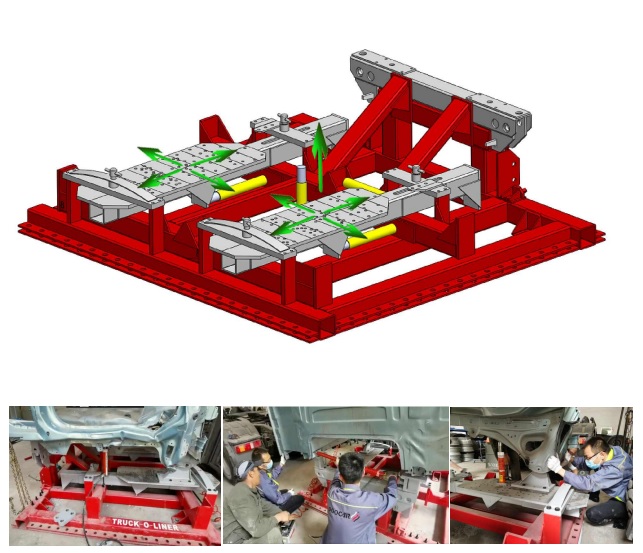

Part 2 Cab straightening system

Truck-O-Liner cab straightening system is composed of cab bench, straightening jigs, straightening pulling tower, straighteing fixture + straightening hydraulic stretching components. The collision cab is fixed by the correcting tooling fixture, and the base of the damaged cab can be restored to the correct position by straightening and pressing by using the hydraulic power in the X, Y, and Z three-dimensional directions of the straightening cab bench. The straightening cab tower and fixtures, hydraulic straightening device can effectively repair the cab column and roof.

A Cab bench DO201

Truck-O-Liner cab bench DO201 is a solid, strong and stable work platform, which can work efficiently and simplify the maintenance of the truck cab. It consists of a strong base and fixing kit, the base can be fixed on the I-beam track of the workshop, or can be fixed on the existing ground with the help of expansion bolts. The fixing kit is movable, which is conducive to the installation and fixing of the cab, and it is very easy to fix even a badly damaged collision cab.

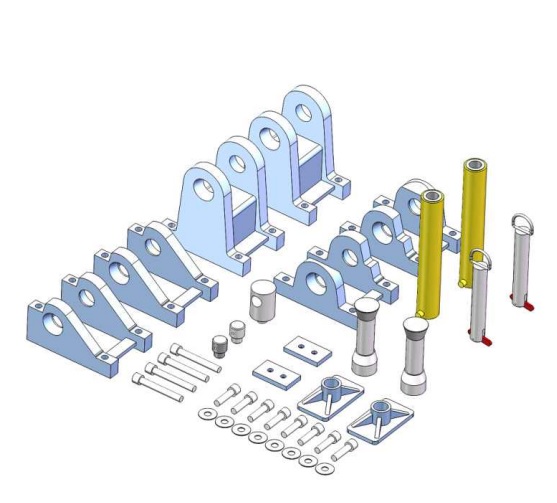

B cab bench adapter kit

According to the actual structure of different truck models, Truck-O-Liner has designed a special fixture to accurately and firmly fix the vehicle on the straightening cab bench, which facilitates quick orthotic restoration of the cab.

Truck-O-Liner has supplied adapter kits for truck workshops of Volvo, Scania, Daimler Benz, MAN, Hino, FAW Jiefang, Dongfeng Commercial, Sinotruk, Foton Auman, Shaanxi Automobile etc.

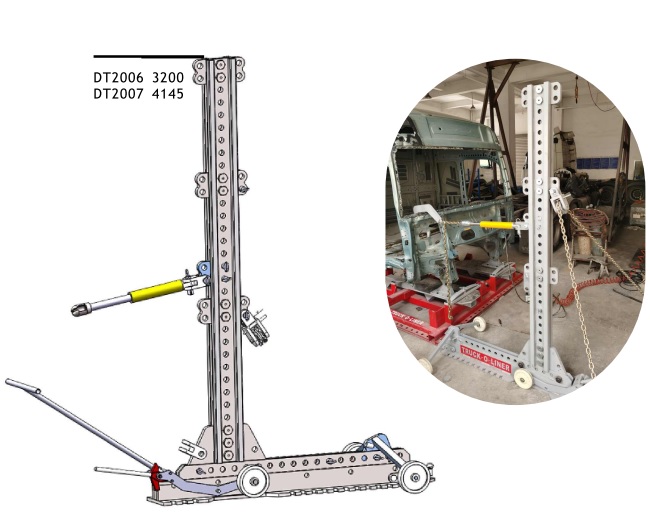

C. Cab tower DT2006/DT2007/ DO2010/2011

The straightening cab tower can cooperate with the cab bench to perform various hydraulic straightening and jacking repairs on the base of the collision cab; it can perform hydraulic straightening repairs on the driving cab column and roof; multiple oil cylinders can be used at the same time for multi-angle straightening repair work. It is also possible to correct and repair collision passenger cars.

D. Pulling fixture + straightening hydraulic pulling device assembly

The function of the correction pulling fixture and the straightening hydraulic pulling assembly is mainly to accurately and firmly fix the damaged part, and to fix and hydraulically straighten the door frame column of the driver's cab.

E. Floor anchoring and I beam anchoring

Floor beams: The Truck-O-Liner frame straightening system is based on the use of l-beams cast flush with the workshop floor. Straightening work is to be done without ramps and the workshop can be used for other purposes.

Truck-O-Liner straightening trolleys, floor attachment etc. are anchored to these floor beams. Furthermore, Truck-O-Liner's cab and bus straightening equipment can also be anchored securely into these floor racks.

Floor anchoring: The floor anchoring is easy to install in your workshop floor in order to ffx the cab tower. The cab tower is fastened with a bolt in the front and chain expanders in the rear. When the ”expander holes” are not in use they can simply be covered by a protective cover.

The floor anchoring is exceptional when it comes to repair of minor damage, as for this bus. In this case the cab tower is fixed with a nose bracket directly in th expander hole at the front and with chains at the rear. The tower is pretensioned with an impact wrench. The pulling angle is quickly adjusted sideways and the tower locked into position with a pin.

Part 3 Truck frame straightening system equipment

Truck-O-Liner frame straightening and repair system can effectively correct lateral bending, vertical bending, twisting deformation, Efficient correction and repair of the frame (including trailer) with deformed corners and partial frame steel beam deformation through the combination of Y-direction press, Z-direction press, frame locker, and C-type correction riveting pliers, The equipment is made of high-strength alloy steel, which fully guarantees the strength of the equipment during the straightening and repair of commercial vehicle frame girders; the American high-pressure hydraulic system is adopted, which is powerful, and can easily repair damaged frame girders.

A. Frame press DO25ST/DO26ST

Both DO25ST press-pull Y-direction press and DO26ST support Y-direction press are made of high-strength alloy steel, high strength, which can meet the increasing maintenance requirements of commercial vehicle frames. It is fully equipped with various high-strength connecting plates, which can meet the pressure and tension repair work of various models and various parts. The frame press is scientifically designed, small in size, high in strength, strong in power, and widely used.

DO25ST press-pull Y-direction frame press is equipped with 25 tons of high-pressure hydraulic cylinders imported from the United States with strong power, which can easily straighten the heavy truck frame. It is equipped with heavy-duty moving wheels imported from Germany and coupled with a unique center of gravity optimization design make operation simple and easy.

DO26ST support the Y-direction press is equipped with heavy-duty moving wheels imported from Germany, and with a unique optimized center of gravity design, make its operation easier.

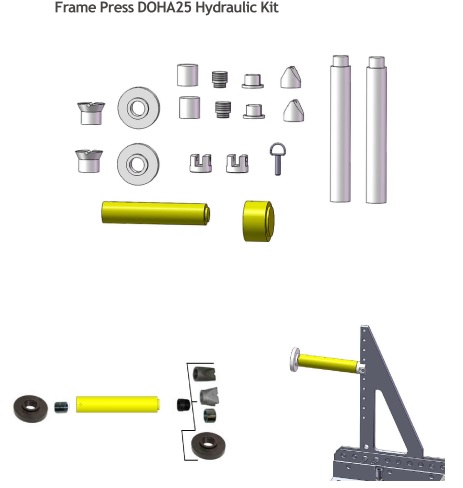

B. Frame press hydraulic kit DOHA25

DOHA25 high-pressure hydraulic components can be matched with DO26ST, turning DO26ST into a press-pull Y-direction press with the same function as DO25ST. After the DOHA25 module is equipped with a hydraulic pump station, the damaged frame can also be straightening and repaired in front, rear, left, right and diagonal directions.

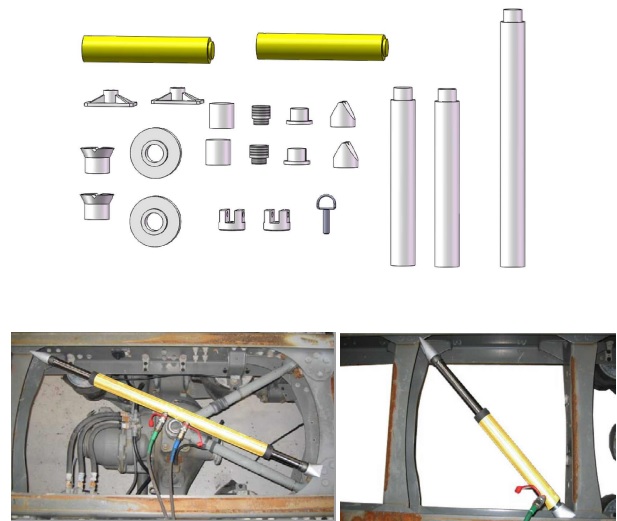

C. Truck body straightening hydraulic kits DOHA10

After the DOHA10 component is equipped with a hydraulic pump station, the damaged frame can also be straightened and repaired in front, rear, left, right and diagonal directions.

D1 Vertical press DO2513

DO2513 is used to correct the vertical deformation of the frame, equipped with a 25-ton high-pressure hydraulic cylinder imported from the United States, with strong power, light overall weight and easy handling.

D2 Vertical press DO2480

DO2480 Z-direction vertical press can be matched with the frame locker and Y-direction press; it can effectively repair the Z-direction vertical deformation of the frame. It is equipped with a 25-ton high-pressure hydraulic cylinder, which is powerful and easy to straighten. It is equipped with heavy moving wheels, it is easy to move. It is equipped with mechanical heightening and locking devices, it can perform hydraulic jacking and correction in a wide range and safely.

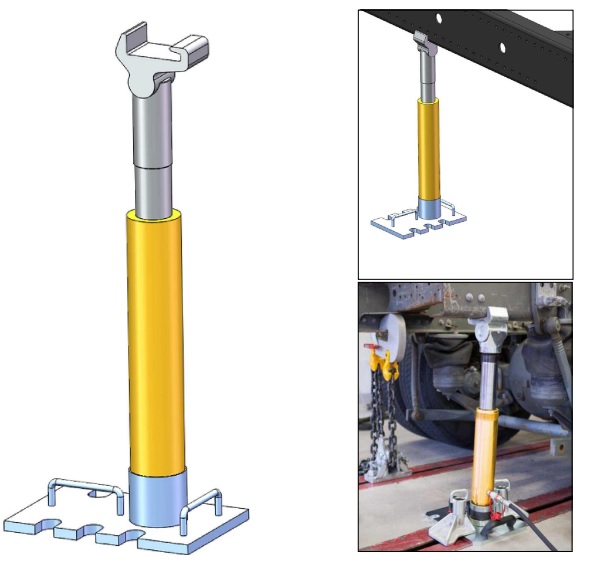

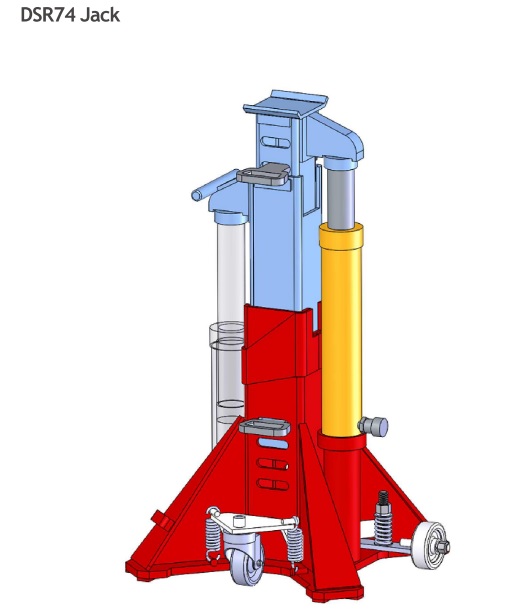

D3 Vertical press jack DSR74

DSR74 Z-direction vertical press can be matched with the frame locker and Y-direction press; it can effectively repair the Z-direction vertical deformation of the frame. It is equipped with a 25-ton high-pressure hydraulic cylinder, which is powerful and easy to straighten. It isequipped with heavy-duty moving wheels, which make it easy to move. It is equipped with mechanical heightening and locking devices, it can perform hydraulic jacking and straightening in a wide range and safely.

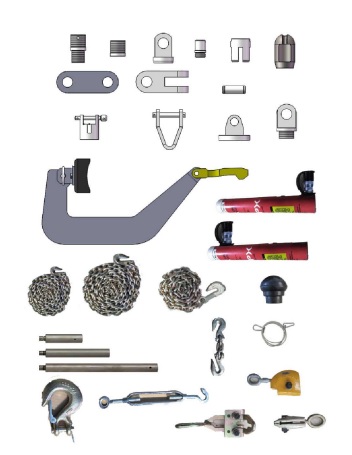

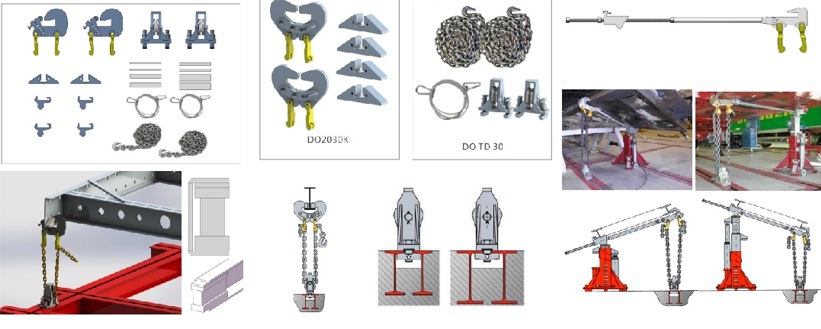

E Straightening accessories

The frame locking device must be used in conjunction with the Z-direction vertical press, and it has an efficient correction and repair effect on vertical deformation, twist deformation, and diagonal deformation of the frame.

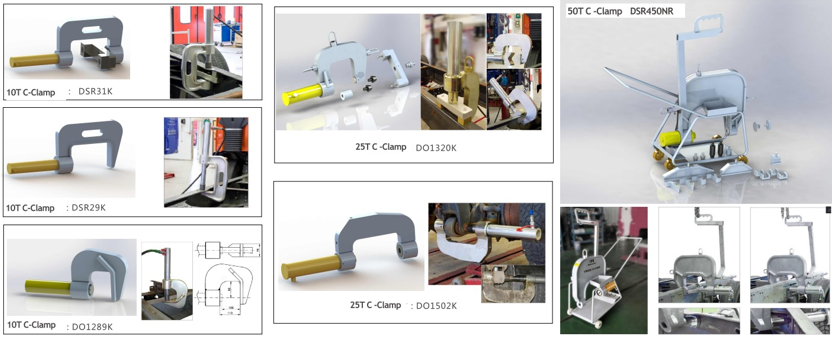

F. C-clamps

Truck-o-Liner C-type pliers have the functions of straightening, riveting, bushing replacement, etc. The products cover the 10-ton C-type pliers for repairing small local deformation of the frame, to the 50-ton C-type for large deformation and cold riveting of the frame clamp. It can meet the maintenance and body repair of heavy vehicles, can be used as a good supplement to existing equipment, and can be purchased and used independently.

Related Products

+8618863316058

+8618863316058 +8618863316058

+8618863316058