| Name: | frame machine hydraulic ram |

|---|---|

| Brand: | DOOCAR |

| Origin: | China or USA |

| INQUIRY |

Product Description

Hydraulic ram is one important component of auto body frame machine and pulling post. The drive-on system and pulling system of the frame machine are both realized through hydraulic kit, so the hydraulic ram is the key and essential component of frame machine. Generally it contains 10 Ton hydraulic pull back ram, 10 Ton hydraulic ram for pulling post, 16 Ton hydraulic ram for frame machine lifting, 25 Ton hydraulic ram for auto collision repair bench.

1. Principle and function of hydraulics

Hydraulic is a type of transmission. Hydraulic transmission use liquid as a working medium, and use the pressure of liquid to transmit power.

A complete hydraulic system consists of five parts, that is energy device, actuating device, control adjustment device, auxiliary device, liquid medium.

The role of the actuating element (hydraulic cylinder and hydraulic motor) of the hydraulic system is to convert the pressure of the liquid to mechanical energy, so as to obtain the required straight line to move or rotate.

2. Application of hydraulic ram and pump in auto body frame machine

Frame machine is a car repair equipment that is used to correct and repair the car body that is damaged and deformed due to collisions at an accident.

Working principle: Positioning the car body that needs to be repaired on the frame machine and pull the body to the opposite of the collision direction to restore the body by straightening system. The drive-on function and pulling function of frame machine are achieved by the hydraulic system. So the hydraulic kit is the key and necessary component of frame machine.

3. Hydraulics parts

(1) Energy device is the hydraulic pump. Its role is to convert the mechanical energy into pressure energy, which is the power part of the hydraulic transmission.

(2) Actuating device - oil cylinder and hydraulic motor, which is to convert the pressure energy into mechanical energy, the oil cylinder does a linear motion, and the motor is rotating.

(3) Controlling device - the pressure valve, flow valve, and direction valve. Their function is to adjust the speed of the liquid motivation as needed, and control the pressure, flow, and flowing direction in the hydraulic system.

(4) Auxiliary components: pressure gauge, hose, fast connector, etc.

(5) Working medium: refers to the hydraulic oil in various hydraulic transmission, which go through the oil pump and hydraulic motor to achieve energy conversion.

4. Oil ram classification (low pressure and high pressure)

(1).25MPa is called a low -pressure ram.

(2).25MPa-40MPa is called mid-pressure ram.

(3).40MPA-100MPa is called a high-pressure ram

(4).100MPa above is called ultra -high pressure ram

5. How to choose the hydraulics?

(1). There are many types of hydraulic pumps, including gear pumps, leaf pumps, screw pumps, axial plunger pumps, and radial plunger pumps. When the hydraulic pump is selected, it should be comprehensively analyzed according to the host conditions, power, component efficiency and work performance.

(2). There are two types of oil pipes and hose used in the hydraulic system. The oil pipes we choose should have sufficient stream section and pressure capacity. At the same time, we should try to shorten the pipeline to avoid rapid turning and cross -sectional changes.

(3). Selection of fast connection

A. According to the type of fluid, temperature, please select the types of body materials suitable for fluids, temperature on the body, and fast connector of sealing materials.

B. Depending on the pressure of the liquid, please select a fast connector with pressure resistance suitable for fluid pressure.

C. confirms that the selected fast connector connection thread should be consistent.

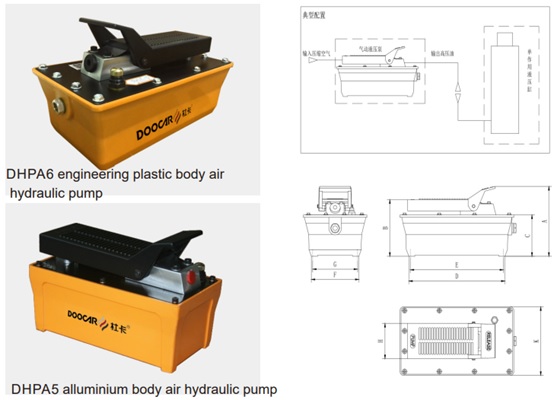

Hydraulic pump specification:

| Pump | A | B | C | D | E | F | G | H | K |

| model | mm | mm | mm | mm | mm | mm | mm | mm | mm |

| DHPA6 | 189 | 154 | 109 | 282 | 258 | 143 | 122 | 92 | 179 |

| DHPA5 | 186 | 154 | 109 | 249 | 232 | 121 | 107 | 92 | 136 |

| model | Usable oil capacity | Pressure rating | Air source pressure | Oil displacement(L/min) | Oil tank material | Oil outlet thread | weight | packing size | |

| L | Mpa | Mpa | No load | load | in | kg | mm | ||

| DHPA6 | 2.3 | 70 | 0.7-1.0 | 0.8 | 0.16 | Engineering plastic | 3/8-18 NPT | 8.3 | 360*220*210 |

| DHPA5 | 1.6 | 70 | 0.7-1.0 | 0.8 | 0.16 | aluminum | 3/8-18 NPT | 7.8 | 305*175*210 |

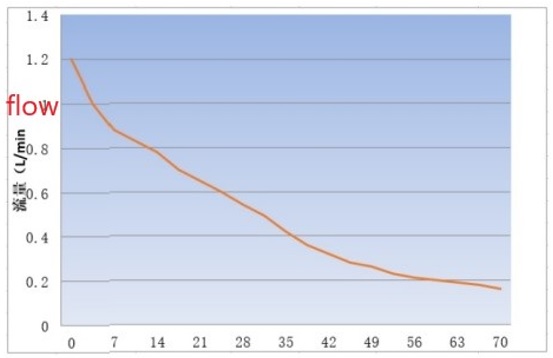

Pneumatic pump works under the condition of air pressure at 0.7MPa, and the relationship between output oil pressure and flow

Properties:

1. Widely used as the power source of various stress tools.

2. Internal safety valve design to avoid ultra -high pressure damage.

3. Engineering plastics, aluminum or steel body can be provided.

4. The surface of the paint is resistant to corrosion and beautiful.

High -pressure hydraulic hose

● Used to require special applications, the safety factor is 4: 1.

● The maximum work pressure is 700bar.

● Four layers of design, two of which are high -strength wire woven layers.

● The external layer is a polyurethane material, which provides maximum wear resistance.

● The volume expansion under pressure is small, which is conducive to improving the efficiency of the safety system.

● All models are equipped with ripple -like rubber cover to prevent damage to improve life and durability.

Hydraulic ram

● The outer ring thread, plunger threads and bottom installation holes make it convenient for positioning (for most models).

● Design to use it in any installation position.

● The removable handle makes it fixed and convenient.

● High -intensity alloy steel is durable.

● Most models can provide high -strength reset spring of nickel plating body.

● Strong corrosion resistance on the surface of the paint.

● The dust -proof sealing circle can reduce pollution and extend the service life of the hydraulic ram.

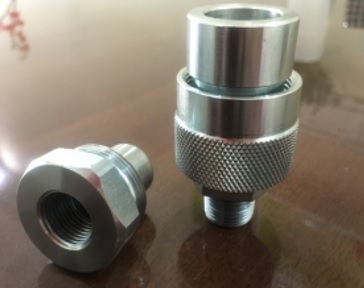

Hydraulic fast male female joint

● 3/8 "large flow connection.

● Most of the standard parts of the hydraulic ram.

● When space and interface allows, it is recommended for all pumps and hydraulic rams.

● "Two -in -one" dust caps that can be used at the same time for female or male joints.

● For small hydraulic rams and manual pumps.

Pressure gauge

●Know at a glance from BAR and KN dual -scale display

●All the pressure sensing parts are sealed by silicon oil densely, and durable

●the surface size of the pressure sheet is 100mm

●Simple installation

●The case is the structure of anti -corrosion stainless steel structure

| model | origin | ram | scales | unit | G thread | ||||

| psi | bar | KN | bar | KN | psi | NPTF | |||

| D-10B | China | 10 Ton | - | 0-700 | 0-100 | 10 | 1 | - | 1/2’’ |

Connectors and valve

| model | description |

| DJ-100 | 3/8 "NPT live joints |

| DZ-W1 | 3/8 "NPT right -angle elbow |

| DZ-W2 | Hydraulic direct connection |

| DZ-W3 | Hydraulic direct connection |

model | desciption | connector | pressure |

| NPTF | bar | ||

| V-82 | ENERPAC throw valve | 3/8'’ | 0-700 |

| D-82 | Domestic throttle valve | 3/8'’ | 0-700 |

| V-66 | ENERPAC manually one -way throttle valve | 3/8'’ | 0-700 |

| V-10 | ENERPAC automatic damping valve | 1/2'' | 0-700 |

| D-10 | Streaming valve | 3/8'' | 0-700 |

D-11 | Streaming valve | 3/8'’ | 0-700 |

| model | description | Pressure gauge | Male terminal | Female terminal | length |

| NPTF | NPTF | NPTF | mm | ||

| GA-3 | ENERPAC connector | 1/4'’ | 3/8'’ | 3/8'’ | 133 |

| DA-3 | Domestic connector | 1/4'’ | 3/8'’ | 3/8'’ | 133 |

| DA-2 | Domestic connector | 1/4'’ | 3/8'' | 3/8' ' | 123 |

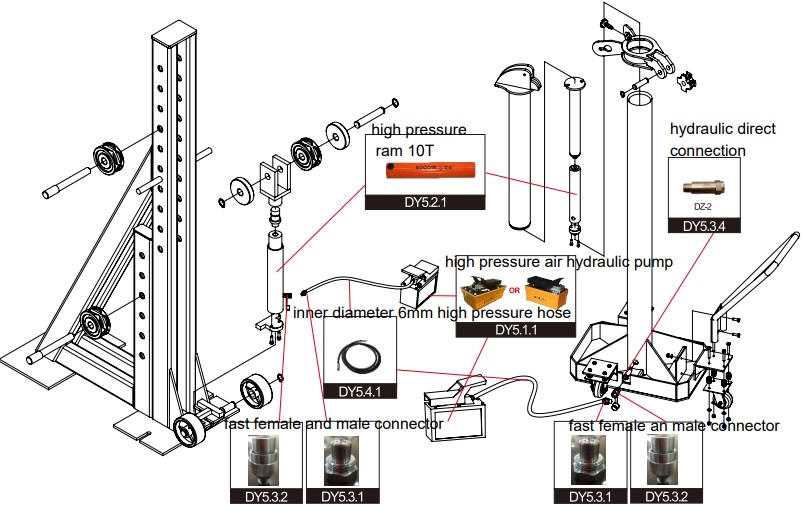

Hydraulic ram and pump on auto body frame machine

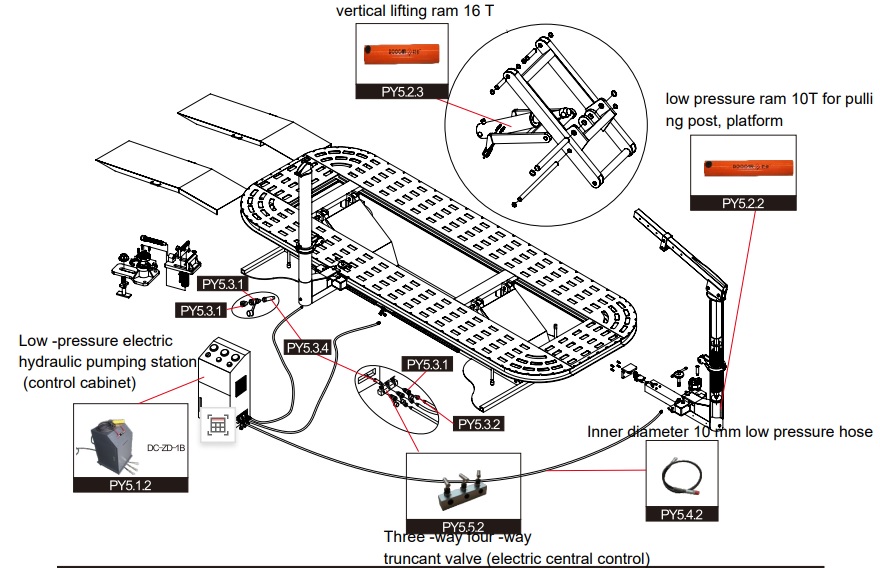

hydraulic ram and pump for auto body floor pulling system:

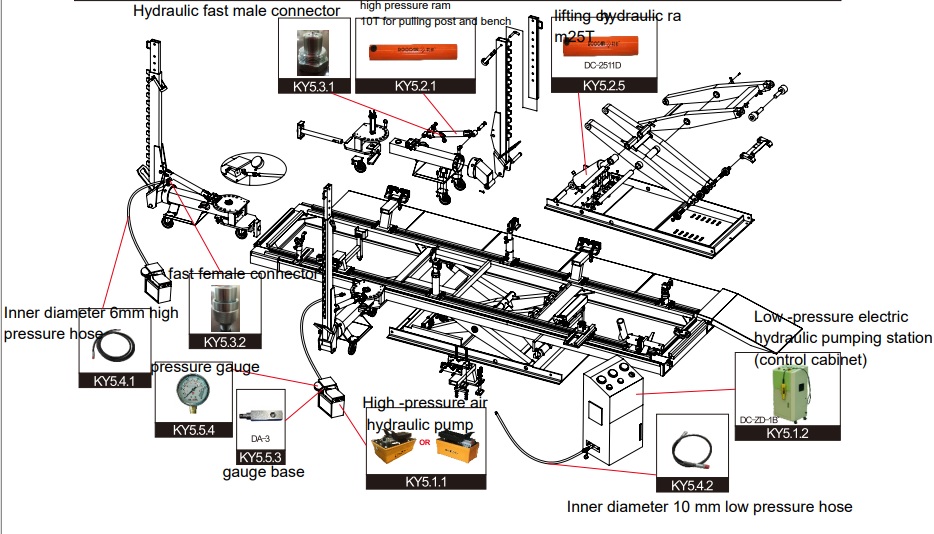

hydraulic ram and pump for car frame rack machine:

hydraulic ram and pump for auto collision repair bench:

Related Products

+8618863316058

+8618863316058 +8618863316058

+8618863316058