News

Auto body measuring equipment comparison

1. Three -dimensional measurement system

(1). The principle of the three -dimensional measurement system is to measure the car chassis and car body with the three coordinates of X, Y, and Z. The three -dimensional measurement at home and abroad is set to 0 points based on the current Mitchell data. It usually has 4-5 horizontal ruler in the X direction. There are 0-3.8 meters to 4.2 meters of ruler zone (according to the error allowed by the national standard ruler zone to 2-3 mm); the Z direction is the horizontal ruler assembled on the X direction, there is a telescopic weight cylinder plus measurement header to measure auto chassis.

Disadvantages:

(1) The length of the longitudinal ulnar in the Y direction reaches 3.8 meters-4.2 meters. According to the current domestic technology, it is not guaranteed in a straight degree and flatness.

(2) When getting on the car, the center of the car should be unified with the center of the correction platform. The height of the vehicle must be equal. When installing a three -dimensional ruler, the center of the horizontal ruler and the vertical ruler must be unified with the center of the vehicle and the correction platform. These are not available in the actual operation process. If you can't reach it, you must adjust the height and left and right positions of the main folder, and adjust the central unity of the three -dimensional ruler, longitudinal ruler, and the center of maintenance of the vehicle. It is time -consuming and laborious.

(3) Since the assembly of the three -dimensional ruler is processed by machinery, the number is large, and the accuracy after assembly is not guaranteed.

(4) Since the three -dimensional ruler is assembled by multiple aluminum alloy materials, it occupies a lot of space on the maintenance platform and affects the maintenance of the vehicle.

2. Electronic measuring equipment for auto chassis and auto body

There are currently two types of electronic measurement equipment, including domestic ones, the price is 20,000-40,000 yuan, and the imported equipment price is between 150,000 and 260,000 or even higher.

For electronical measuring equipment made in China, the main aluminum alloy material, plus the sliding seat, and the infrared launch device (that is, infrared shooting head) and the receiving board, then it becomes electronic measurement equipment. Database incomplete or no database. At present, it cannot meet the basic requirements of vehicle detection and maintenance at all.

For all imported electronic measurement equipment, there are currently few production in Europe and North America. The price is expensive. However, the requirements for body shop and environment and supporting services are relatively high.

(1) For auto body shop, when buying, a experienced technician is required for special training. After operation training, the measurement equipment can be used well.

(2) Environmental requirements: large storage areas is required. There must be no water, oil, and humidity. When used, it is necessary to clean the vehicle maintenance area clean. For the humid and dusty environment of the air, it directly affects its service life.

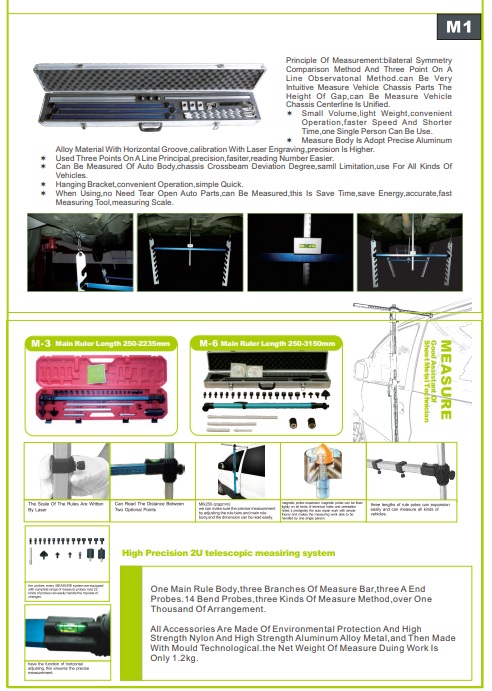

3. Auto body measuring tram gauge

The MEASURE auto body measuring tram gauge can accurately measure the size and internal structure size of the car body. Actually, a conclusion was obtained: After using the MEASURE automotive tram gauge, the working hours were reduced by 25%, and the one -test qualification rate increased by 30%. MEASURE tram gauge is good helper for body shop technicians. It is most practical and economical car body measurement tools.

+8618863316058

+8618863316058 +8618863316058

+8618863316058